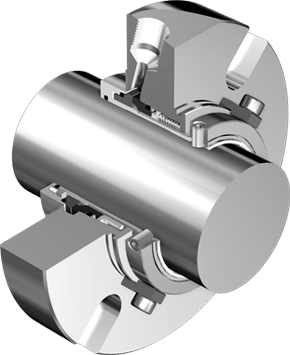

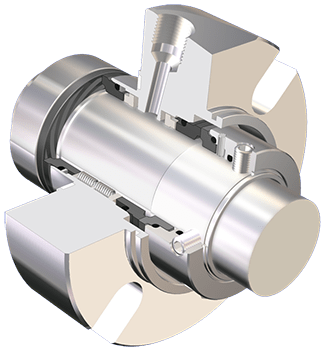

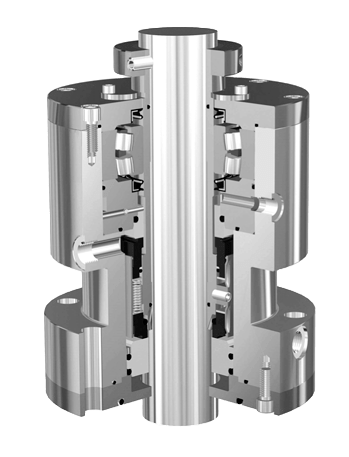

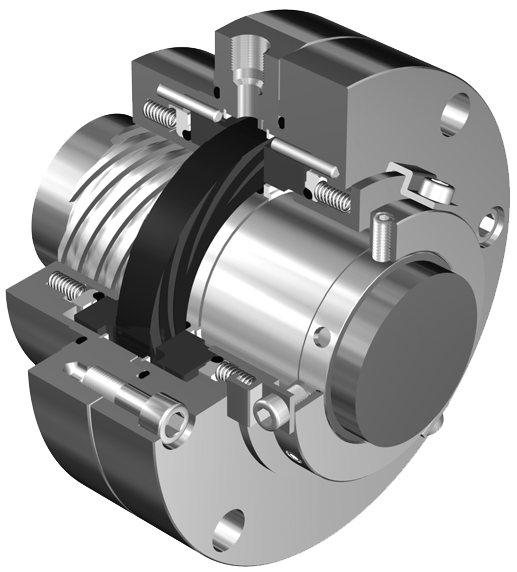

GK/GN

The GK seals are designed mostly for process pumps used in refining and petrochemical industries, in chemical industry and coking plants, and in particular in pump installations with a high level of explosion risks and increased emissions of volatile substances into the environment. The GK seal requires continuous supplying with filtered barrier gas (most commonly nitrogen) of pressure ~ 0.2 MPa higher than the sealed medium pressure.